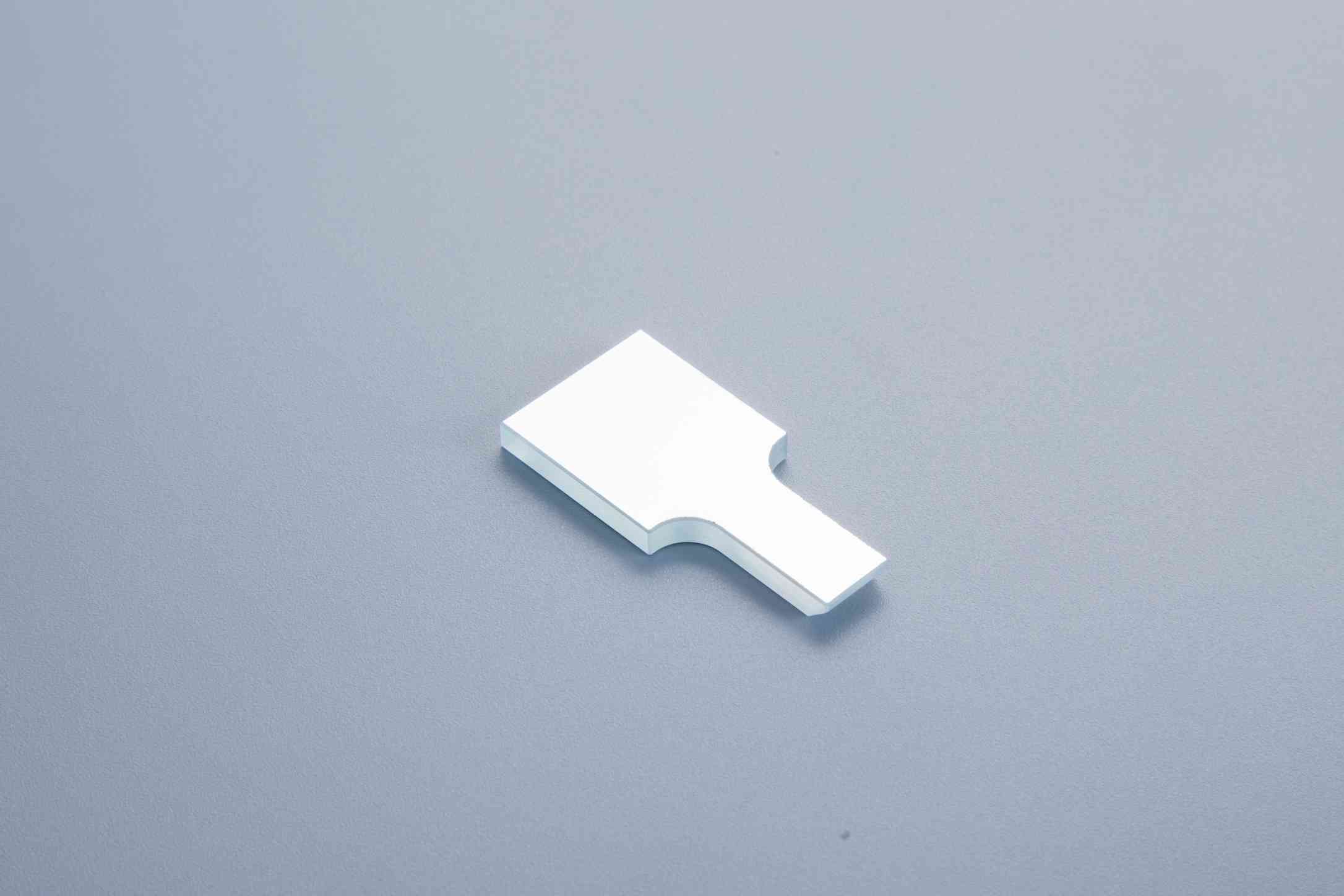

Aluminium coating Mirror for Slit lamp

Product Description

This kind of mirrors are commonly used for slit lamps in ophthalmology to provide a clear and accurate image of the patient's eye. The aluminum coating on a slit lamp mirror works as a reflective surface, allowing the light to be directed at various angles through the patient's pupil and into the eye.

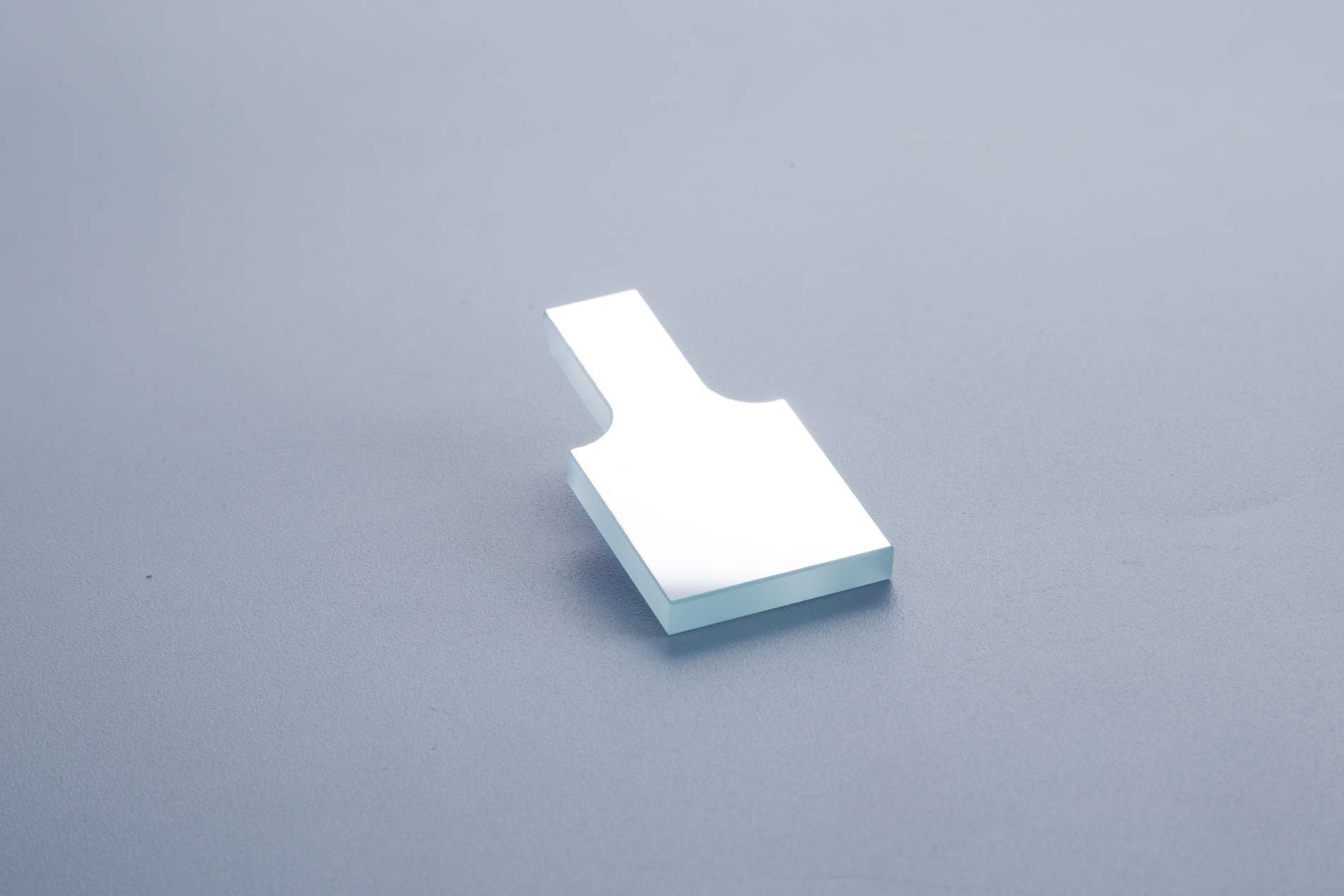

The protective aluminum coating is applied through a process called vacuum deposition. This involves heating aluminum in a vacuum chamber, causing it to evaporate and then condense onto the surface of the mirror. The thickness of the coating can be controlled to ensure optimal reflectivity and durability.

Protective Aluminum mirrors are preferred over other types of mirrors for slit lamps because they have a high reflectivity, are resistant to corrosion and abrasion, and are lightweight. The reflective surface of the mirror needs to be maintained to ensure optimal performance, and therefore, care must be taken to avoid scratching or damaging the mirror surface during use or cleaning.

The slit lamp is an important diagnostic tool used by ophthalmologists to examine the eye. A slit lamp allows doctors to examine different parts of the eye, such as the cornea, iris, lens, and retina. One of the important components of the slit lamp is the mirror, which is used to provide a clear and sharp image of the eye. Aluminum-coated mirrors have grown in popularity in recent years due to their superior optical performance and durability.

Aluminized mirror is a high-quality mirror made of glass. The glass is coated with a thin layer of aluminum, giving the mirror enhanced reflectivity and optical properties. The mirror is designed to be placed in the slit lamp, where it reflects light and images from the eye. The aluminum coating on the mirror provides near-perfect reflection of light, ensuring that the resulting image is clear and bright.

One of the standout features of aluminized mirrors is their durability. The mirror is made of high-quality materials that resist damage from physical shocks, scratches, and chemicals. The mirror is designed to withstand the rigors of everyday use, making it a reliable and cost-effective component of the slit lamp.

The aluminum-coated mirror also provides excellent contrast. The high reflectivity of the mirror allows ophthalmologists to see the details of the eyes clearly, making it easier to diagnose various eye diseases. Due to its superior optical performance, aluminum-coated mirrors have become an essential tool for ophthalmologists in their daily diagnosis and treatment.

In summary, the aluminum-coated mirror is an important part of the slit lamp, providing ophthalmologists with clear and sharp eye images. The high-quality materials used in the mirror's construction make it reliable and durable, ensuring it can withstand the rigors of everyday use. Its superior optical performance and long-lasting durability make it an excellent investment for any ophthalmologist looking to enhance their diagnostic capabilities.

Specifications

|

Substrate |

B270® |

|

Dimensional Tolerance |

±0.1mm |

|

Thickness Tolerance |

±0.1mm |

|

Surface Flatness |

3(1)@632.8nm |

|

Surface Quality |

60/40 or better |

|

Edges |

Ground and Blacken, 0.3mm max. Full width bevel |

|

Back Surface |

Ground and Blacken |

|

Clear Aperture |

90% |

|

Parallelism |

<3’ |

|

Coating |

Protective Aluminum Coating, R>90%@430-670nm,AOI=45° |