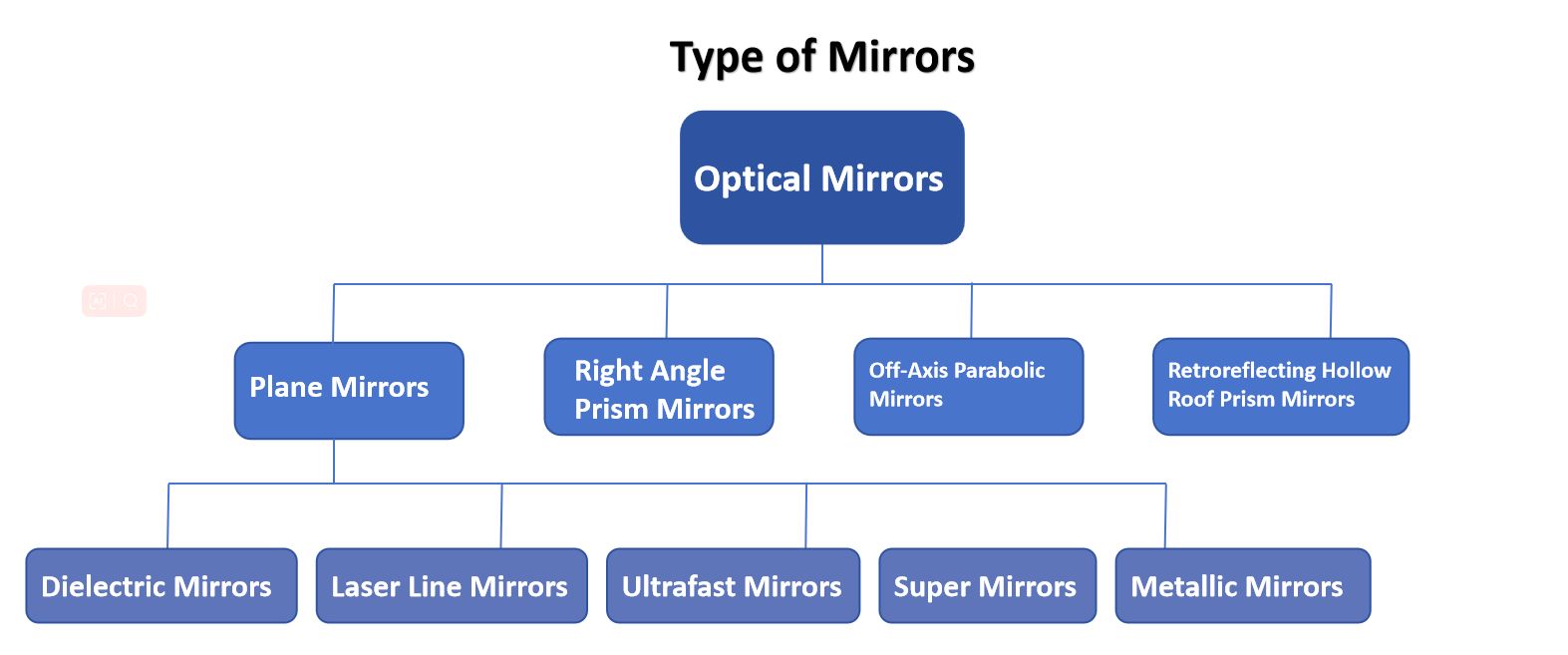

Types of mirrors

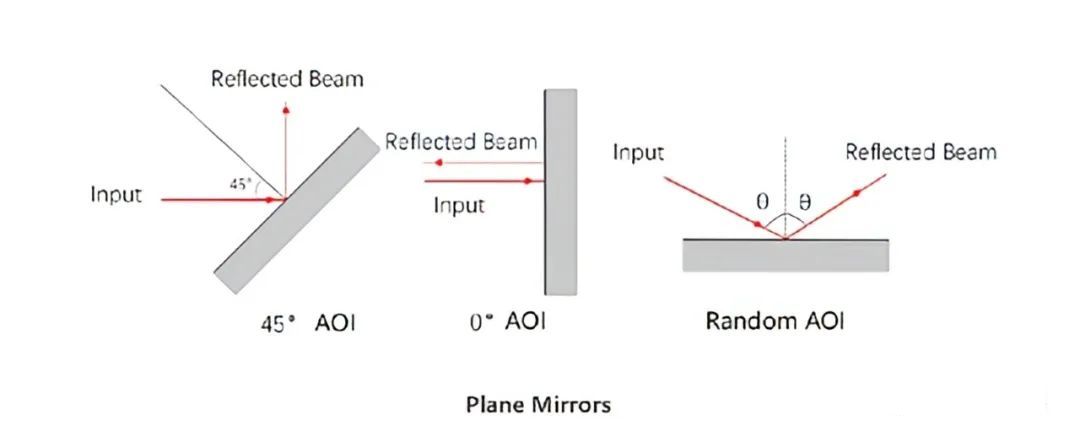

Plane Mirror

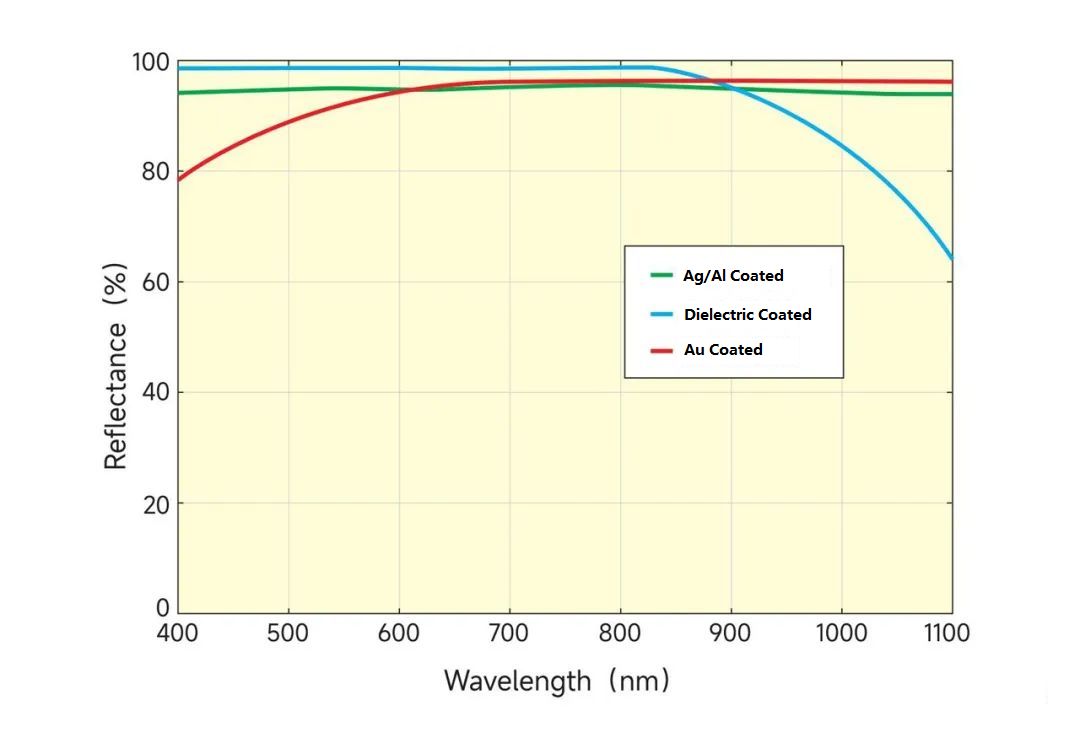

1.Dielectric coating mirror: Dielectric coating mirror is a multi-layer dielectric coating deposited on the surface of the optical element, which produces interference and enhances reflectivity in a certain wavelength range. The dielectric coating has high reflectivity and can be used in a wide wavelength range. They do not absorb light and are relatively hard, so they are not easily damaged. They are suitable for optical systems using multi-wavelength lasers. However, this kind of mirror has a thick film layer, is sensitive to the angle of incidence, and has a high cost.

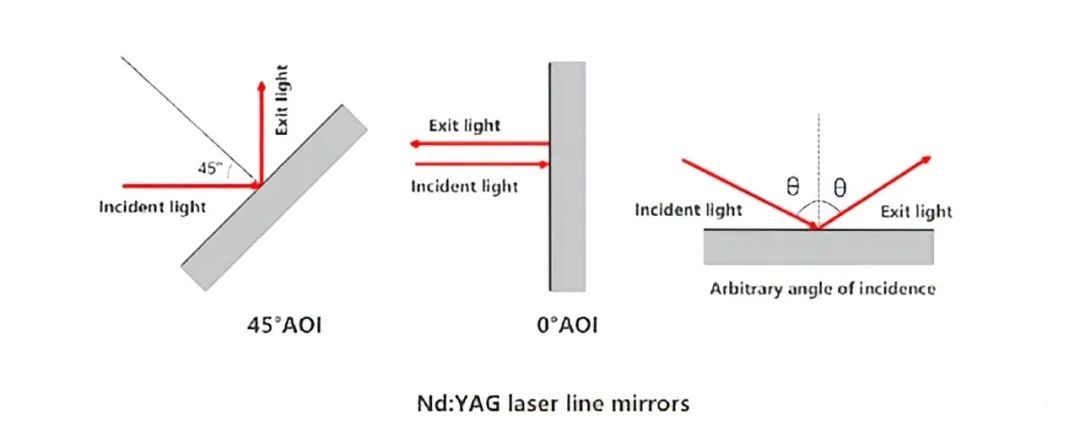

2.Laser Rays Mirror: The base material of the laser rays mirror is ultraviolet fused silica, and the high reflectivity film on its surface is Nd:YAG dielectric film, which is deposited by electron beam evaporation and ion-assisted deposition process. Compared with K9 material, UV fused silica has better uniformity and lower coefficient of thermal expansion, making it especially suitable for applications in the ultraviolet to near infrared wavelength range, high power lasers and imaging fields. Common operating wavelengths for laser rays mirrors include 266 nm, 355 nm, 532 nm, and 1064 nm. The incident angle can be 0-45° or 45°, and the reflectivity exceeds 97%.

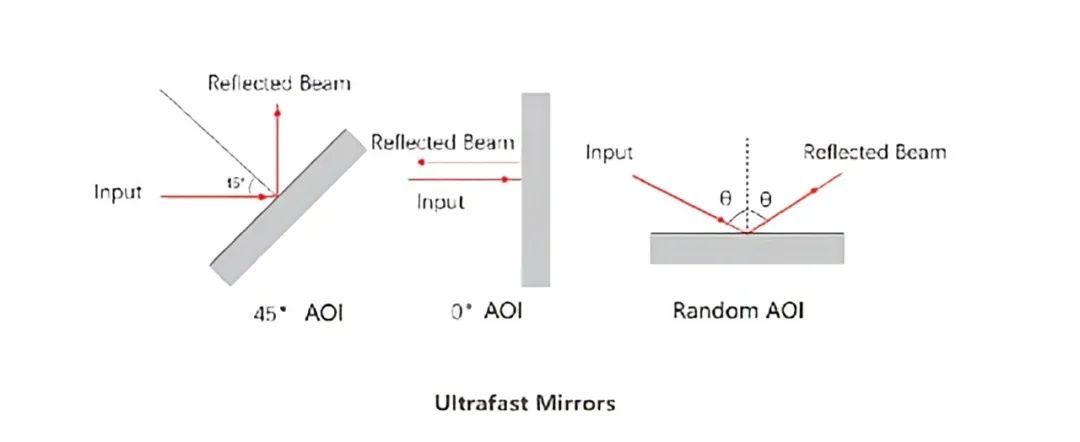

3.Ultrafast mirror: The base material of the ultrafast mirror is ultraviolet fused silica, and the high reflectivity film on its surface is a low group delay dispersion dielectric film, which is manufactured by ion beam sputtering (IBS) process. UV fused silica has a low coefficient of thermal expansion and high thermal shock stability, making it ideal for high power femtosecond pulsed lasers and imaging applications. Common operating wavelength ranges for ultrafast mirrors are 460 nm-590 nm, 700 nm-930 nm, 970 nm-1150 nm, and 1400 nm-1700 nm. The incident beam is 45° and the reflectivity exceeds 99.5%.

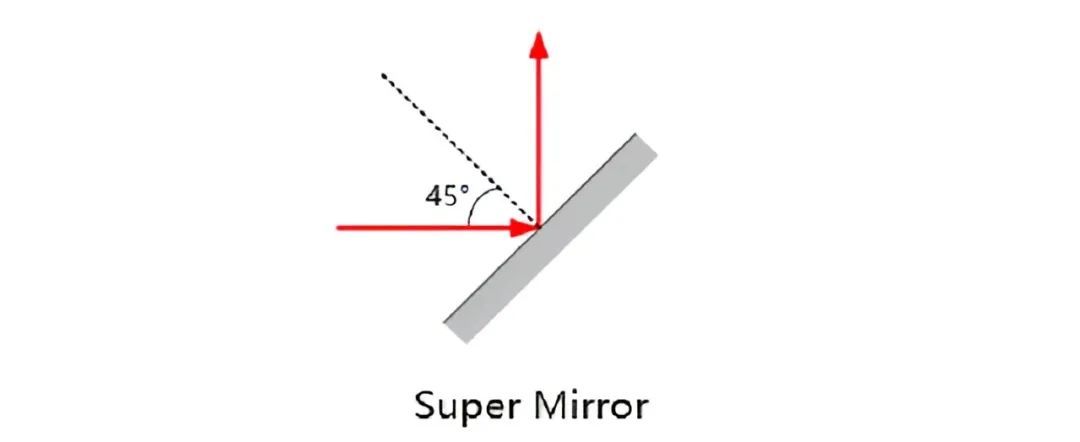

4.Supermirrors: Supermirrors are fabricated by depositing alternating layers of high and low refractive index dielectric materials on a UV fused silica substrate. By increasing the number of layers, the reflectivity of the super-reflector can be improved, and the reflectivity exceeds 99.99% at the design wavelength. This makes it suitable for optical systems requiring high reflectivity.

5.Metallic Mirrors: Metallic mirrors are ideal for deflecting broadband light sources, with high reflectivity over a broad spectral range. Metal films are prone to oxidation, discoloration or peeling off in high humidity environments. Therefore, the surface of the metal film mirror is usually coated with a layer of silicon dioxide protective film to isolate the direct contact between the metal film and the air and prevent oxidation from affecting its optical performance.

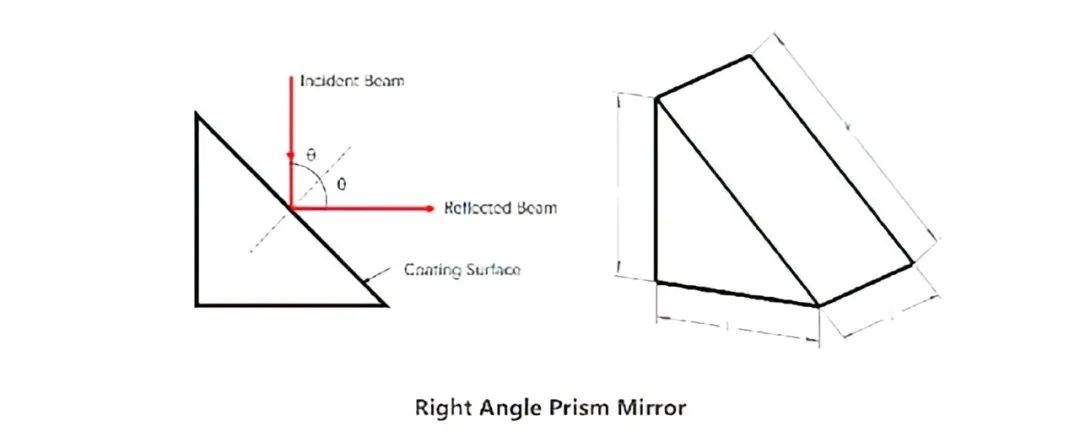

Usually, the right-angle side is coated with an anti-reflection film, while the slant side is coated with a reflective film. Right-angle prisms have a larger contact area and typical angles such as 45° and 90°. Compared to regular mirrors, right-angle prisms are easier to install and have better stability and strength against mechanical stress. They are the optimal choice for optical components used in various devices and instruments.

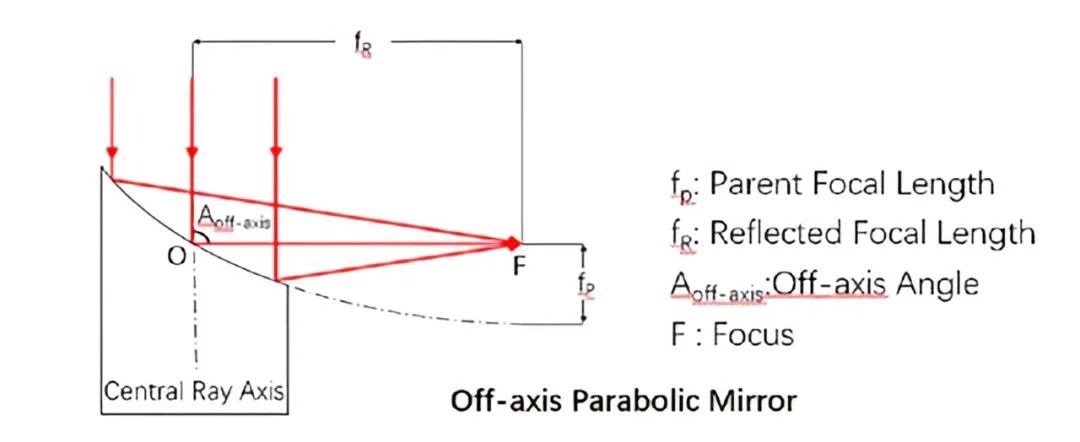

Off-axis Parabolic Mirror

An off-axis parabolic mirror is a surface mirror whose reflective surface is a cutout portion of a parent paraboloid. By utilizing off-axis parabolic mirrors, parallel beams or collimated point sources can be focused. The off-axis design allows separation of the focal point from the optical path. Using off-axis parabolic mirrors has several advantages over lenses. They do not introduce spherical or chromatic aberration, which means that focused beams can be more accurately focused on a single point. In addition, beams passing through off-axis parabolic mirrors maintain high power and optical quality since the mirrors introduce no phase delay or absorption losses. This makes off-axis parabolic mirrors particularly suitable for certain applications, such as femtosecond pulsed lasers. For such lasers, precise focusing and alignment of the beam is critical, and off-axis parabolic mirrors can provide higher precision and stability, ensuring effective focusing of the laser beam and high-quality output.

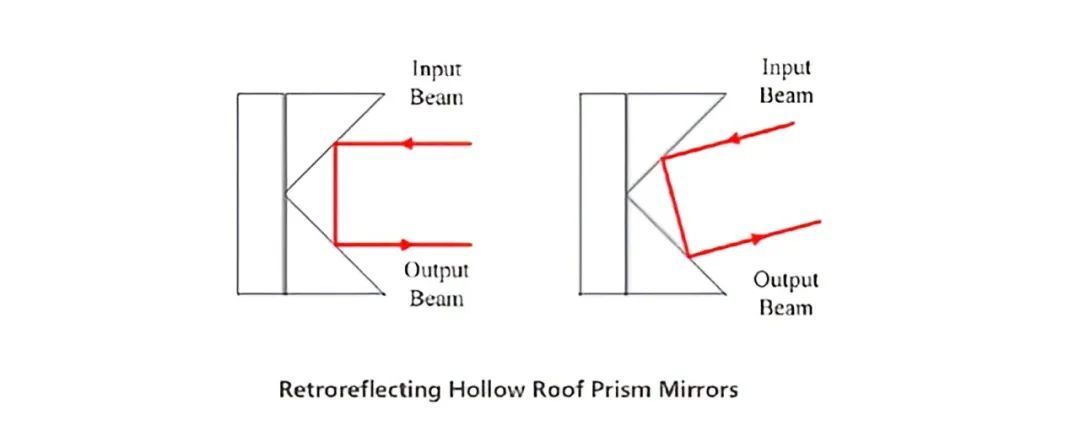

Retroreflecting Hollow Roof Prism Mirror

The hollow roof prism consists of two rectangular prisms and a rectangular base plate made of Borofloat material. Borofloat materials have extremely high surface flatness and excellent optical properties, exhibiting excellent transparency and extremely low fluorescence intensity in the entire spectral range. In addition, the bevels of the right-angle prisms are coated with a silver coating with a metallic protective layer, which provides high reflectivity in the visible and near-infrared range. The slopes of the two prisms are placed opposite each other, and the dihedral angle is set to 90±10 arcsec. The hollow roof prism reflector reflects light incident on the hypotenuse of the prism from the outside. Unlike flat mirrors, the reflected light remains parallel to the incident light, avoiding beam interference. It allows for a more precise implementation than manually adjusting the two mirrors.

Guidelines for the use of flat mirrors:

Post time: Jul-31-2023